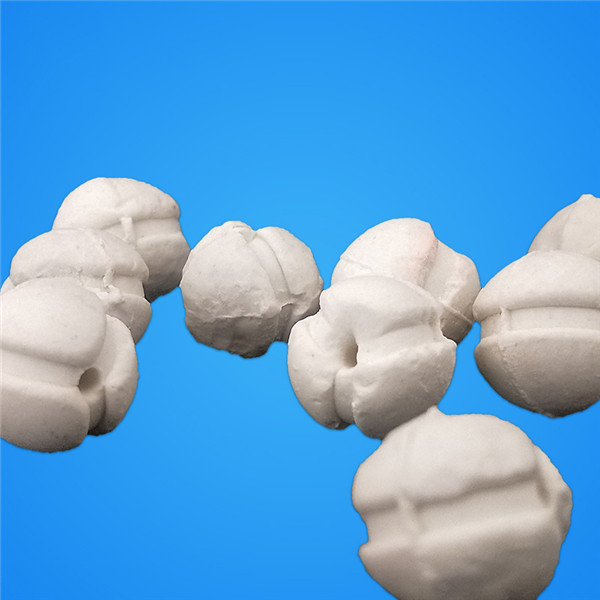

Porous Ceramic Bhora Mugadziri ane saizi yakasiyana

Application

Porous ceramic bhora chigadzirwa chitsva chakagadziridzwa pahwaro hweinert alumina ceramic bhora. Zvinotora dhayamita yebhora seakisi kuvhura gomba. Iyo haina kungova nemamwe masimba emagetsi, kugadzikana kwemakemikari uye kugadzikana kwekupisa, asiwo inowedzera iyo chaiyo nzvimbo. Uye iyo void ratio, nekudaro ichiwedzera kupararira uye kuyerera kwezvinhu, uye kuderedza kuramba kwehurongwa. Inogona kushandiswa zvakanyanya mumaindasitiri epetroleum, kemikari uye gasi rechisikigo kutsiva inert alumina ceramic mabhora secatalyst inovhara mafirita ekutsigira.

Zvinhu Zvenyama

| Type | Feldspar | Feldspar- Molai | Molai Stone | Molai- Corundum | Corundum | |||||

| Item | ||||||||||

| Chemical Content | Al2O3 | 20-30 | 30-45 | 45-70 | 70-90 | ≥90 | ||||

| Al2O3+ SiO2 | ≥90 | |||||||||

| Fe2O3 | ≤1 | |||||||||

| Kuwedzerwa kwemvura (%) | ≤5 | |||||||||

| Kuramba Asidhi (%) | ≥98 | |||||||||

| Alkaki Resistance (%) | ≥80 | ≥82 | ≥85 | ≥90 | ≥95 | |||||

| Kushanda Tembiricha(°C) | ≥1300 | ≥1400 | ≥1500 | ≥1600 | ≥1700 | |||||

| Kupwanya Simba (N/Chidimu) | Φ3mm | ≥400 | ≥420 | ≥440 | ≥480 | ≥500 | ||||

| Φ6mm | ≥480 | ≥520 | ≥600 | ≥620 | ≥650 | |||||

| Φ8mm | ≥600 | ≥700 | ≥800 | ≥900 | ≥1000 | |||||

| Φ10mm | ≥1000 | ≥1100 | ≥1300 | ≥1500 | ≥1800 | |||||

| Φ13mm | ≥1500 | ≥1600 | ≥1800 | ≥2300 | ≥2600 | |||||

| Φ16mm | ≥1800 | ≥2000 | ≥2300 | ≥2800 | ≥3200 | |||||

| Φ20mm | ≥2500 | ≥2800 | ≥3200 | ≥3600 | ≥4000 | |||||

| Φ25mm | ≥3000 | ≥3200 | ≥3500 | ≥4000 | ≥4500 | |||||

| Φ30mm | ≥4000 | ≥4500 | ≥5000 | ≥5500 | ≥6000 | |||||

| Φ38mm | ≥6000 | ≥6500 | ≥7000 | ≥8500 | ≥10000 | |||||

| Φ50mm | ≥8000 | ≥8500 | ≥9000 | ≥10000 | ≥12000 | |||||

| Φ75mm | ≥10000 | ≥11000 | ≥12000 | ≥14000 | ≥15000 | |||||

| Hukuru Density (kg/m3) | 1100-1200 | 1200-1300 | 1300-1400 | 1400-1550 | ≥1550 | |||||

Saizi uye Kushivirira(mm)

| Diameter | 6/8/10 | 13/16/20/25 | 30/38/50 | 60/75 |

| Kushivirira kwedhayamita | ±1.0 | ±1.5 | ±2.0 | ±3.0 |

| Pore dhayamita | 2-3 | 3-5 | 5-8 | 8-10 |