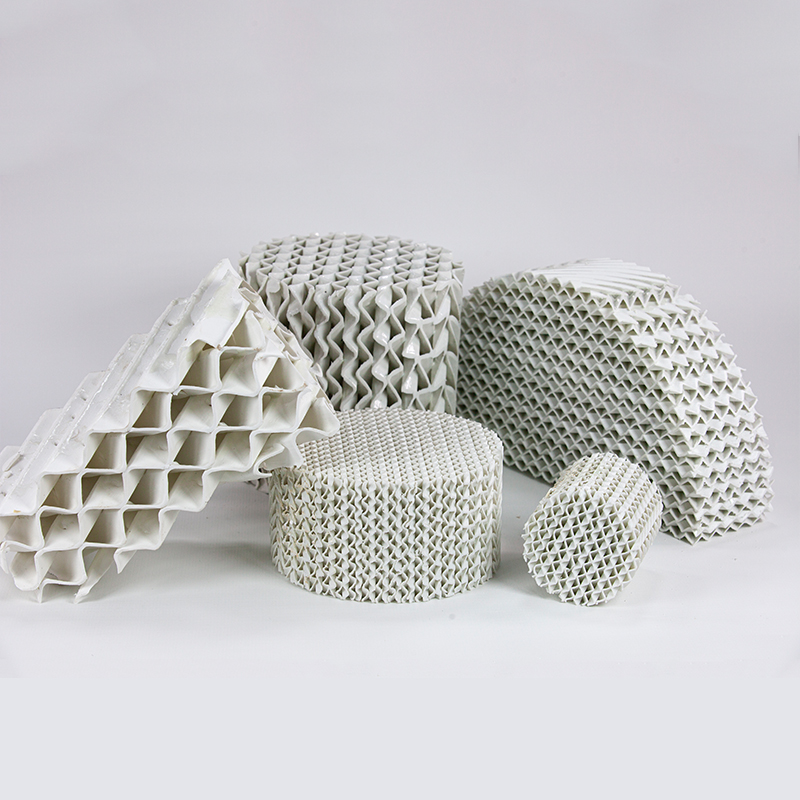

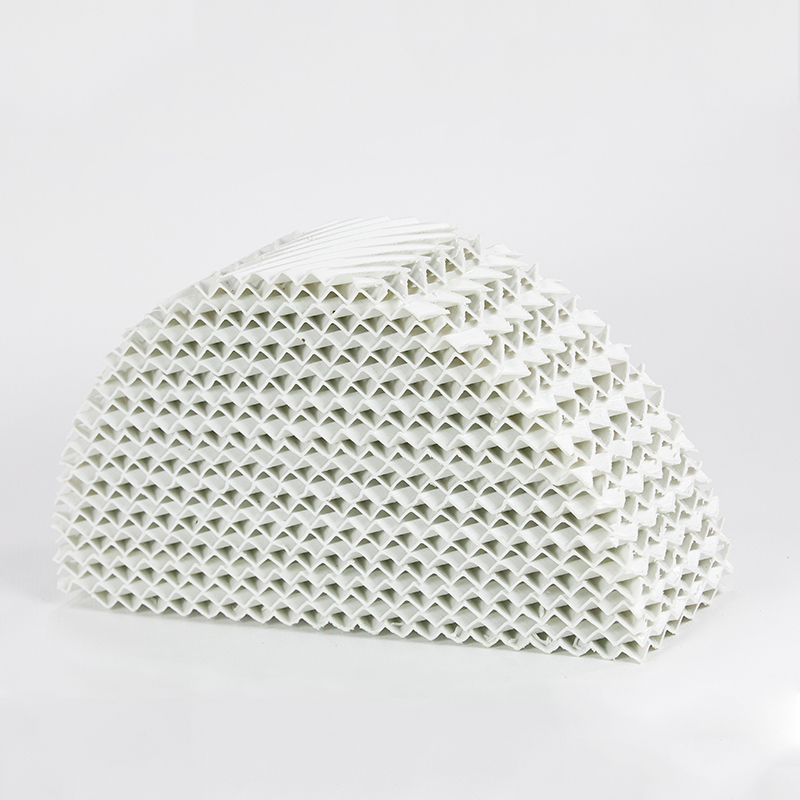

Ceramic Yakarongeka Packing ine mhando 125Y & 250Y

Nekuda kweceramic yakasarudzika dhizaini, yakanaka hydrophilic kuita, nzvimbo yayo inogona kuita yakaonda kwazvo yemvura firimu yemhepo ine mhepo inoyerera uye tortuous chiteshi inogona kusimudzira mhepo asi isingamire kufanana nesimbi yekuzadza mhepo inogona kugadzira ceramic kurongedza, uye kushora kwayo kwekuora, kupisa kwakanyanya kusaita kwesimbi filler haigone kuenzaniswa.Surface chimiro chine yakanaka yekunyorova chivakwa, inogona kumhanyisa kuyerera kwemvura kunonoka kuyerera. overheating, aggregation, and coking.Ichi chigadzirwa chinogadzirwa nemhando yepamusoro chemakemikari porcelain clay raw material processing uye inova, inopikisa kutonhora kwepamusoro uye kudzvinyirira kwakanyanya, kugadzikana kwakanaka kwemakemikari uye simba guru, inotakura inokodzera kutsigira marudzi akasiyana-siyana ezvinokonzera.

Chemical Analysis

| Composition | Value |

| SiO2 | ≥72% |

| Fe2O3 | ≤0.5% |

| CaO | ≤1.0% |

| Al2O3 | ≥23% |

| MgO | ≤1.0% |

| Zvimwe | 2% |

Pfuma Yenyama

| Index | Value |

| Chaiyo giravhiti (g/cm3) | 2.5 |

| Kutorwa kwemvura (wt%) | ≤0.5 |

| Asidhi kuramba (wt%) | ≥99.5 |

| Kurasikirwa mukupisa (wt%) | ≤5.0 |

| Max. Kupisa Kwekushanda.(℃) | 800 |

| Kupwanya simba (Mpa) | ≥130 |

| Kuoma kwaMoh (Chikero) | ≥7 |

Technical Date

| Spec. | Nzvimbo chaiyo (m2/m3) | Kuwanda kwehuwandu (kg/m3) | Void ratio (%) | Obl. Angle | Kudonha kwepressure (mm Hg/m) | Theo. Plate (m-1) | Hydraulic dhayamita (mm) | Mvura inotakura (m3/m2h) | Max. Factor m/s (Kg/m3)-1 |

| 125Y | 125 | 320 | 90 | 45 | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

| 250Y | 250 | 420 | 80 | 45 | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

| 350Y | 350 | 470 | 78 | 45 | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

| 450Y | 450 | 520 | 72 | 45 | 4 | 4 | 7 | 0.2-100 | 1.8 |

| 550Y | 550 | 620 | 74 | 45 | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700Y | 700 | 650 | 72 | 45 | 6 | 7 | 5 | 0.15-100 | 1.3 |